Ocean

3D-Printed Artificial Reefs

3D-printed artificial reefs, marine habitat restoration, artificial reef materials, low-carbon clay reefs, Baltic Sea reef restoration, biomimetic reef design, gaia.eco

Across the Baltic Sea, the removal of natural boulder reefs for construction has left vast stretches of sandy seabed with few viable habitats for marine life. A Danish harbor project is pioneering a restoration approach that combines 3D printing with sustainable biomaterials to create artificial reefs that replicate the ecological function of those lost boulder formations. The reefs are designed to provide shelter, breeding areas, and attachment surfaces for native marine species — effectively jumpstarting biodiversity recovery in degraded coastal environments.

The Problem: Lost Boulder Reefs

Natural boulder reefs once provided complex, hard-substrate habitats across the Baltic Sea floor. Their removal transformed diverse marine landscapes into barren sandy beds where most organisms struggle to establish themselves. Without hard surfaces for attachment and crevices for shelter, populations of fish, crustaceans, echinoderms, and sessile organisms have declined significantly in affected areas.

How the Artificial Reefs Work

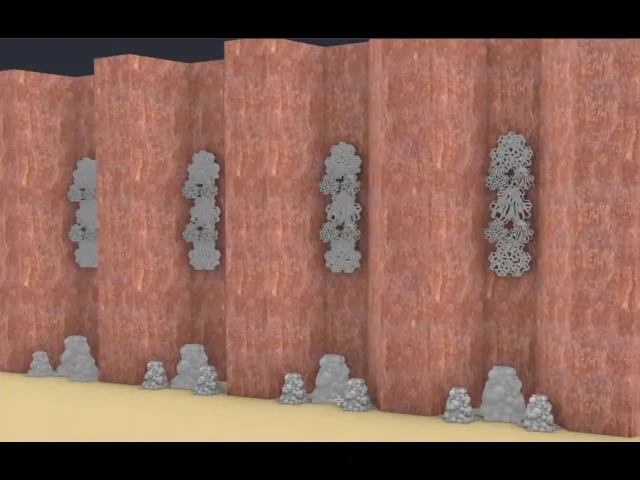

The reefs are strategically installed in harbor crevices and underutilized spaces where they do not interfere with boat traffic or port operations. Their design draws directly from the structural characteristics of natural boulder reefs — rough, porous surfaces with varied geometry that offers hiding spots, attachment points, and flow-through water circulation.

Key design principles include:

Custom geometry via 3D printing. Additive manufacturing enables precise control over reef shape, porosity, and surface texture. This allows designers to optimize conditions for marine organism settlement in ways that traditional concrete or rock-pile approaches cannot.

Rough surface textures. The surface finish of the printed structures encourages larval settlement and attachment by sessile organisms such as barnacles and algae.

Habitat complexity. Varied internal and external structures provide shelter for mobile species like fish, crabs, and starfish at multiple life stages.

Materials: Low-Carbon Clay and Shell Biomass

Material selection is central to the project's ecological and environmental goals. The reefs are constructed from a low-carbon clay mixed with crushed shells (biomass), chosen for several reasons:

Reduced carbon footprint. The clay requires significantly less energy to produce than Portland cement-based alternatives, and the kilns used for firing are compatible with renewable energy sources.

Neutral pH. Unlike concrete, which can leach alkaline compounds into surrounding water, the clay-shell composite maintains a neutral pH that allows marine organisms to attach immediately after installation.

Biomimetic properties. The chemical and physical composition of the clay-shell mix closely resembles natural marine substrates, improving habitat suitability for native species.

Colonization Results

Pilot deployments have demonstrated rapid ecological uptake. Within one month of installation, reef surfaces achieved near-complete coverage by sessile organisms, primarily barnacles and algae. Subsequent monitoring recorded colonization by a range of species including fish, shore crabs, starfish, and various invertebrates — confirming that the structures function as effective habitat for both sessile and mobile marine life.

Managing Invasive vs. Native Species

A persistent challenge in artificial reef projects is the risk that invasive species will dominate new surfaces before native organisms can establish themselves. This project addresses that challenge through deliberate material and design choices:

Natural material advantage. The clay-shell substrate provides a surface more chemically familiar to endemic species than synthetic alternatives, giving native organisms a competitive edge during early colonization.

Surface texture optimization. The 3D-printed rough surfaces are tuned to favor the attachment mechanisms of native sessile species commonly found in the Baltic region.

Level playing field approach. Rather than attempting to exclude invasive species entirely, the design philosophy aims to remove artificial advantages that synthetic materials might confer on non-native organisms, allowing natural competitive dynamics to play out.

Use Cases

Harbor and port restoration. Ports and harbors with degraded seabeds can install reefs in underutilized spaces — along quay walls, in unused berths, or beneath docks — to restore local biodiversity without disrupting operations.

Coastal infrastructure integration. New coastal construction projects can incorporate artificial reef modules as part of environmental mitigation, offsetting habitat loss from development activities.

Marine biodiversity monitoring. The rapid colonization rates observed make these reefs effective platforms for studying species recruitment, succession dynamics, and the interplay between native and invasive organisms.

Ecological compensation programs. Regulatory frameworks that require habitat compensation for marine construction can use 3D-printed reef installations as a quantifiable, deployable restoration measure.

Education and public engagement. Visible reef installations in accessible harbor locations offer opportunities for public science communication and citizen-science monitoring programs.

Outlook

The Reef Circular project has drawn recognition from marine restoration experts as a model for scalable, sustainable habitat recovery. The combination of advanced manufacturing, biomimetic material science, and ecological design principles represents a practical template that can be adapted to degraded coastal environments worldwide. Continued monitoring of colonization patterns, species diversity, and long-term structural durability will be essential to refining the approach and building the evidence base for broader adoption.

Join our Community Forum

Any other questions? Get in touch